-

Phone

-

E-Mail

-

WhatsApp/WeChat

Battery components, battery component casings, motors and casings, electronic control casings, transmissions and transmission systems, body parts, etc.

Power generation: solar silicon wafers, glass plates, new photovoltaic materials, etc.

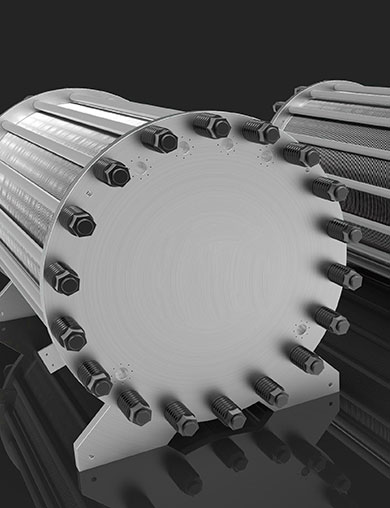

Energy storage: battery casing, tabs, bipolar plates, etc.

Energy storage: battery casing, tabs, bipolar plates, etc.

Copyright © 2024 Skymen Technology Corporation Limited