-

Phone

-

E-Mail

-

WhatsApp/WeChat

Plastic mold cleaning: The surface of plastic molds is often covered with grease, gum and other dirt that is difficult to clean. Through the action of tiny bubbles, ultrasonic cleaners can penetrate into the microstructure, clean every corner of the mold surface, and improve the service life and production efficiency of the mold.

Plastic container cleaning: Plastic containers commonly used in food, medical and other fields are prone to adhering to various substances on their surfaces. Ultrasonic cleaners can quickly and thoroughly remove residues to ensure the hygiene and safety of the containers.

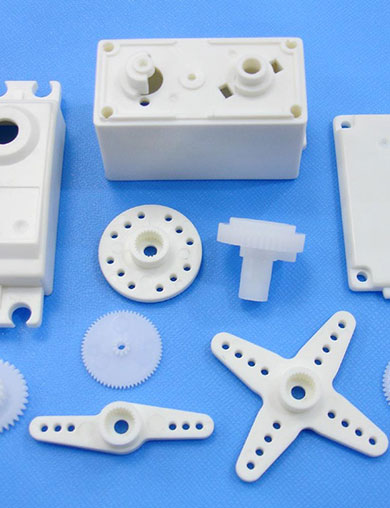

Plastic parts cleaning: In the automotive, electronics and other industries, the surface of plastic parts often needs to be cleaned to remove residues and oil from the production process. The high-frequency vibration of ultrasonic cleaners can effectively remove these difficult-to-treat dirt and improve the quality of parts.

Cleaning of plastic optical components: For plastic optical components that require high-precision surfaces, traditional cleaning methods cannot meet the requirements. Ultrasonic cleaners avoid surface scratches in a non-contact manner and ensure the quality and transparency of optical components.

Copyright © 2024 Skymen Technology Corporation Limited